Cyclic Corrosion Testing chamber ETSP- CCT series

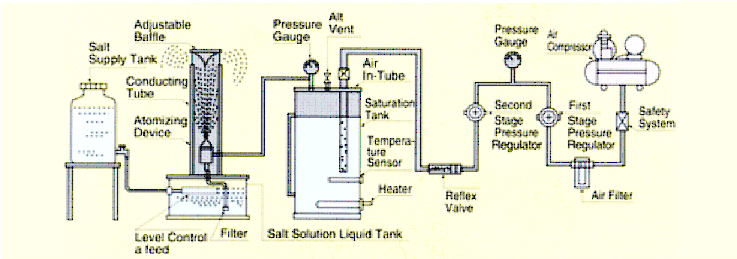

Cyclic Corrosion testing chambers ETSP-CCT series provide possible laboratory simulation of natural corrosion, it is possible to cycle through all of the most significant corrosion environments. Even the most complex test cycles can easily be programmed with the touch screen LCD controller.

- Test space and outer housing are made of non-corrosive material (Internal material: Titanium, External material: Stainless steel 316)

- All piping for air/liquid are made of nylon or polyurethane material

- Unique salt spray atomizer to guarantee uniform salt spray distribution

- Friendly, flexible, up-to date control and management systems

- Allows easy servicing and upgrades

- Oven networking connecting system (RS232/485)

| Temperature range |

RT ~80 ℃ |

| Humidity range |

20 ~ 98% RH |

| Spray volume |

1.5 ± 0.5mℓ/80㎠/h |

| Atomizer |

Fine fog of 5~20 micron droplet size |

| Filter/regulator |

a filter cum air regulator, with pressure from 0~30 PSI |

| Saturator |

Non-corrosive, temperature controlled saturator, Automatic water level controller, Immersion heater |

| Microprocessor controller including self-diagnostics, warning message function |

| Input power requirements |

230V ±10%, 380V ±10%, 50Hz/60Hz, 1Ph/3Ph (Changeable according to customer specification) |

| Model |

Internal dimensions |

External dimensions |

Useful capacity |

| ETSP-CCT 200 |

800x500x500 (WxDxH) mm |

1400x1000x1500 (WxDxH) mm |

200 liters |

| ETSP-CCT 480 |

1000x800x600 (WxDxH) mm |

1600x1300x1600 (WxDxH) mm |

480 liters |

| ETSP-CCT 600 |

1500x800x500 (WxDxH) mm |

2100x1000x1500 (WxDxH) mm |

600 liters |

| ETSP-CCT 1000 |

2600x1500x1500 (WxDxH) mm |

2600x1500x1500 (WxDxH) mm |

1000 liters |

Note Different size of chambers are available on user's demand

- Chart recorder

- PH meter set kit

- Additional nozzle

- Distilled water generator and pump

- Customization available